Moisture is one of the biggest challenges when storing and transporting rubber products. Excess humidity can lead to surface defects, material degradation, mold growth, and reduced shelf life. Selecting the right desiccant ensures that rubber products remain safe, dry, and in optimal condition throughout storage and shipment.

| Silica Gel Desiccant | Clay Desiccant | Molecular Sieve Desiccant |

|---|---|---|

|

|

|

|

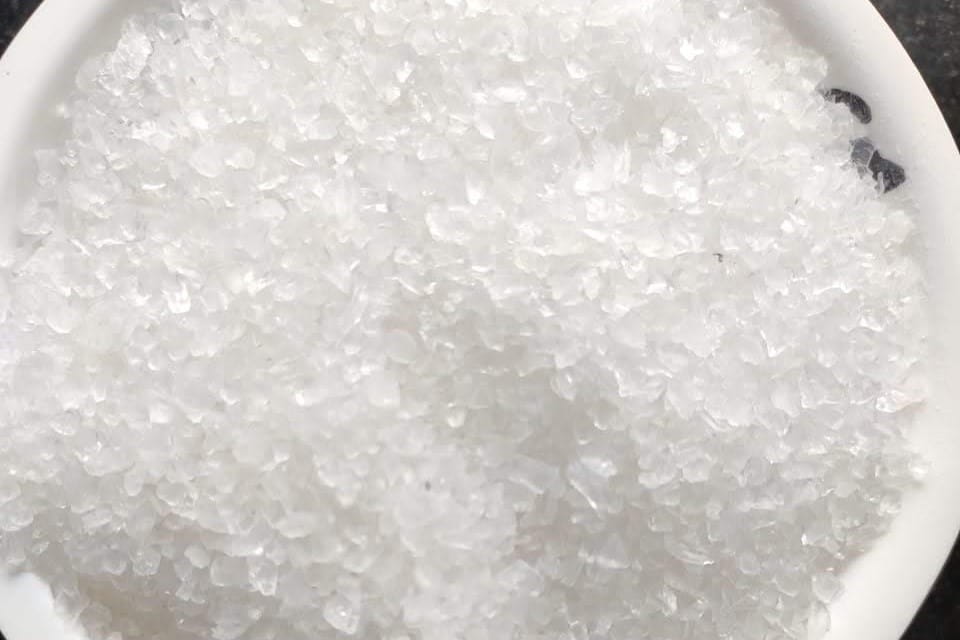

Silica gel desiccant for rubber sheets are ideal for general moisture protection in rubber packaging and tire shipments, with fast-absorbing, easy-to-use sachets. |

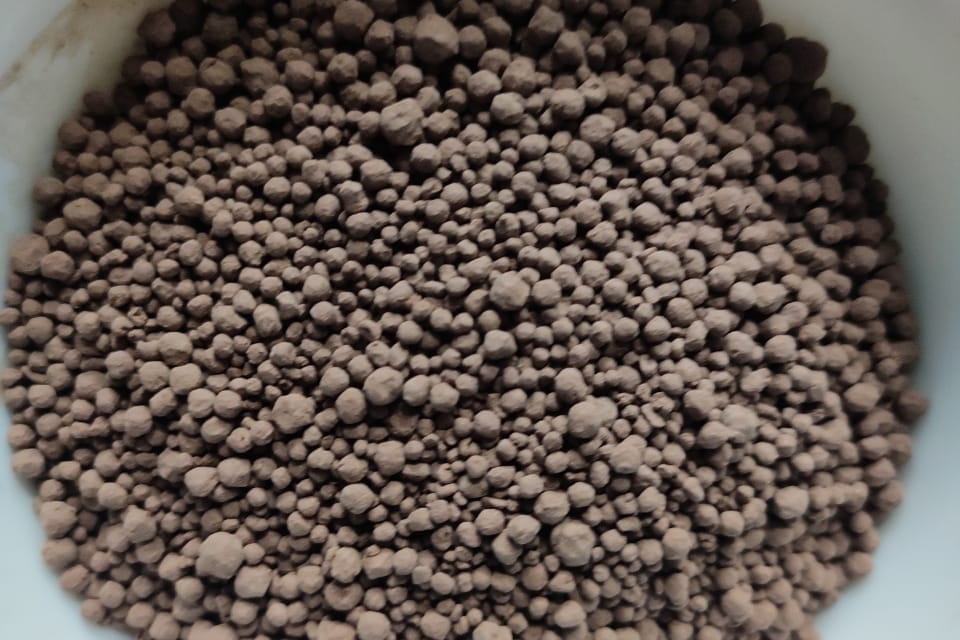

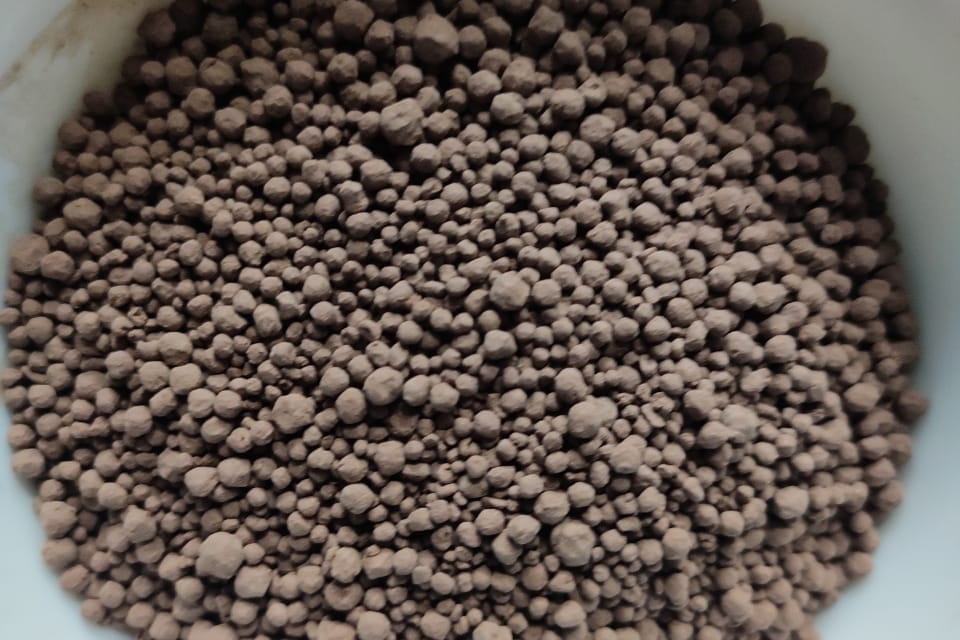

Clay Desiccant is cost-effective option controls moisture in bulk rubber exports and container storage. |

By using molecular sieve desiccants, protect automotive tyre shipments from moisture during shipment, and ensure long-term protection and consistent product quality. |

Silica gel desiccant for rubber sheets are ideal for general moisture protection in rubber packaging and tire shipments, with fast-absorbing, easy-to-use sachets.

Clay Desiccant is cost-effective option controls moisture in bulk rubber exports and container storage.

By using molecular sieve desiccants, protect automotive tyre shipments from moisture during shipment, and ensure long-term protection and consistent product quality.