Moisture is one of the most critical threats to the performance and lifespan of transformers, switchgear, and other power sector equipment. Even small amounts of humidity can lead to operational issues, resulting in equipment failure, reduced efficiency, and higher maintenance costs.

Transformers: Moisture in transformers can cause insulation breakdown, internal corrosion, accelerated aging, and reduced operational efficiency, potentially leading to equipment failure and decreased reliability.

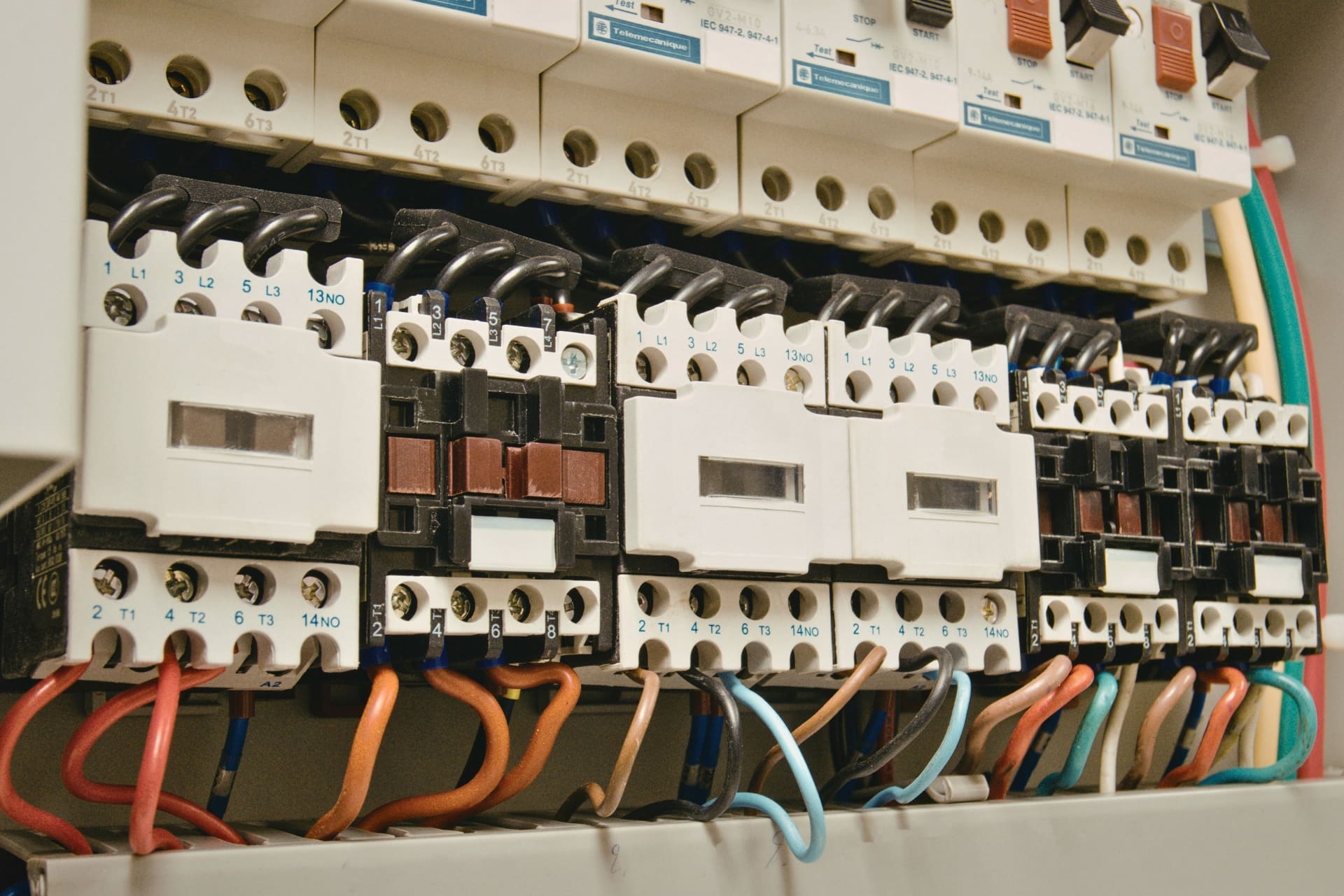

Switchgear: Moisture can lead to corrosion, insulation problems, and electrical sparking in switchgear, reducing reliability, damaging components, and increasing maintenance requirements.

Power Sector Equipment: Humidity can corrode metal surfaces, lower efficiency, shorten equipment lifespan, and increase operational risks across power sector assets.

Cargo desiccant bags are essential during the export of transformers, switchgear, and other power-sector equipment. They absorb excess moisture inside shipping containers, prevent condensation, protect insulation integrity, protect switchgear from humidity during sea shipment, and reduce the risk of corrosion. As a trusted switchgear shipment desiccant manufacturer, industrial cargo desiccants help ensure that equipment arrives at the project site in a safe, dry, and installation-ready condition.

During storage and transportation, electrical equipment is exposed to high humidity, temperature fluctuations, and container condensation, all of which can lead to rust formation, insulation degradation, and reduced operational life. Industrial-grade cargo desiccant bags create a controlled, moisture-free environment inside packaging, containers, and enclosures, providing reliable protection against moisture-related damage throughout transit.

Power sector equipment is highly sensitive to environmental moisture. During export shipping, sea freight, and long-term storage, fluctuating temperatures can lead to condensation inside packaging. VA Pharma Pack’s desiccant bags for power sector equipment absorb excess moisture, maintaining optimal humidity levels and preventing damage to critical electrical components.

Cargo desiccant bags are widely used for:

Silica gel desiccant is ideal for switchgear, transformers, and power sector equipment. Silica gel strongly attracts moisture, effectively lowering humidity in enclosed spaces. In the power sector, it is widely used in desiccant breathers installed on transformers, circuit breakers, and switchgear to prevent moisture ingress.

Cargo desiccant bags are specifically designed for harsh shipping conditions, including ocean freight and high-humidity climates. These moisture absorbers remain effective despite temperature fluctuations, ensuring consistent protection for transformers and switchgear across long supply chains.

Cargo desiccant bags used in the power sector are non-toxic, leakage-free, and environmentally safe. These moisture control solutions comply with international packaging and shipping standards, making them suitable for global exports and industrial applications.

Effective moisture management is essential for maintaining the performance and reliability of transformers, switchgear, and electrical equipment. Cargo desiccant bags provide a proven and dependable solution to safeguard high-value power sector assets from manufacturing to installation. As an industrial container desiccant manufacturer in India, Cargo Desiccant Bag provides advanced moisture control solutions that are designed to ensure maximum protection during storage and transit.